Descripción

What Will You Learn?

Our detailed curriculum will guide you through each stage of the prosthesis design and manufacturing process, combining theory and practice to ensure a comprehensive and applicable understanding. Here’s a look at what you’ll cover in each module:

Module 1: Introduction to Prosthesis Manufacturing

- What is a prosthesis and what is it used for?

- What is an assistive device?

- A brief history of prosthetics

- Types of prosthetics and their applications

- Importance of customization in prosthesis manufacturing

Module 2: Fundamentals of a prosthesis

- Obtaining a base model

- Taking measurements

- Open SCAD:

- What is Open SCAD?

- Basic Navigation

- Application to the Obtained Model

- Tips and Recommendations

Module 3: 3D Modeling and Design

- Introduction to 3D Modeling

- Principles of 3D Design (Isometric Views)

- Lines

- Scales

- Fusion 360 Software

- What is Fusion 360?

- Software Uses

- Navigation

- Basic Principles

- Basic Modeling

- Custom Prosthesis Design Process

Module 4: 3D Printing from Scratch

- What is 3D Printing?

- 3D Printing Fundamentals

- Types of 3D Printers

- Parts of a 3D Printer

- Setup and Calibration

- Modeling and Slicing Software

Module 5: Prosthesis Design and Printing

- Review of Designed Parts

- Preparing Files for 3D Printing

- Selecting Materials for Prosthesis Printing

- Printing and Post-Processing

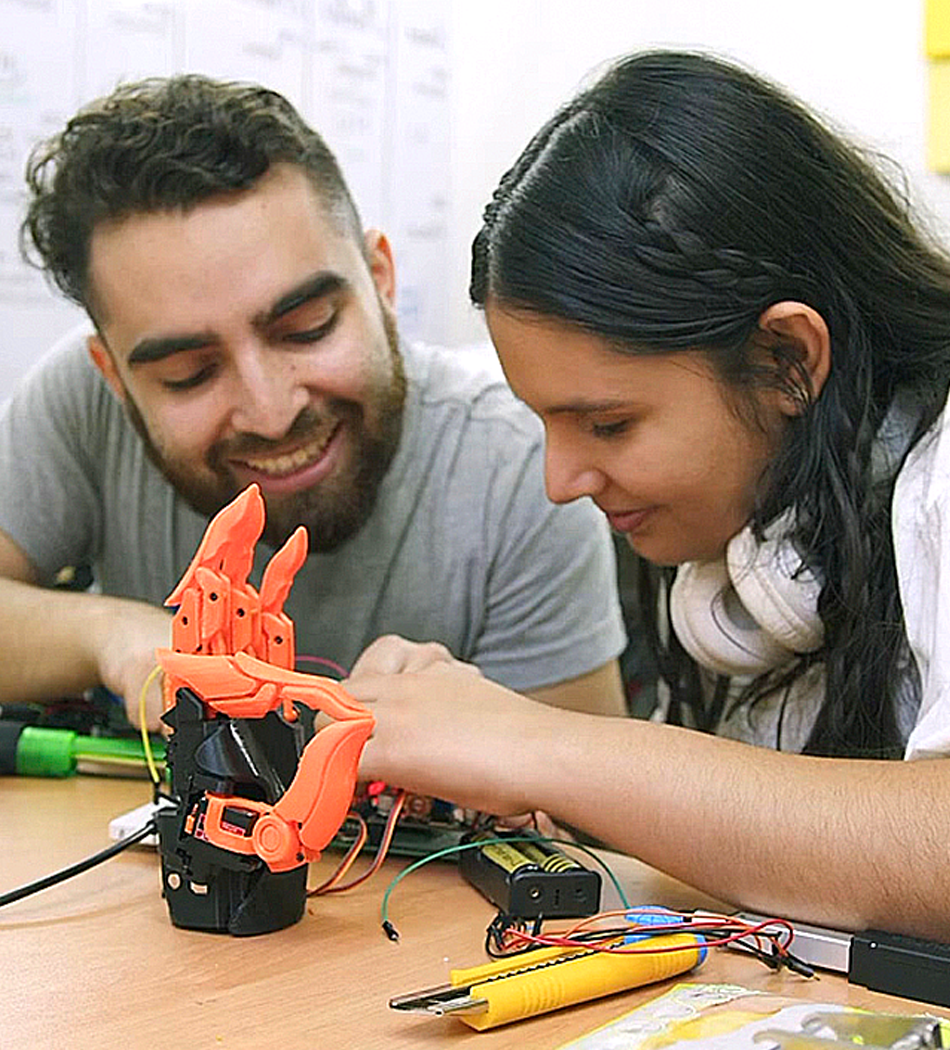

Module 6: Prosthesis Manufacturing and Assembly Process

- Processes and tools for prosthesis assembly.

- Assembly of printed and non-printed components.

- Fitting and testing the prosthesis.

- Ethical and legal considerations in prosthesis manufacturing.

Additional Resources

Invitation to related communities and forums

Recommended tools and materials for development

Final Project

Design and manufacturing of a custom prosthesis

Presentation of the process and results